Non classified area in pharmaceutical industries will be the area where our items have no direct connection with the air & we don’t have controlled airborne particles.

The organization had only lately began a cleaning validation system at enough time on the inspection and it was thought of insufficient by FDA. Considered one of The explanations it was viewed as insufficient was which the business was only seeking evidence on the absence with the previous compound. The company had evidence, from TLC exams within the rinse drinking water, on the existence of residues of response byproducts and degradants with the previous procedure.

Just about every phase is per implementing, building, and testing to certain demands. Techniques for analysis and measurements for Certification are specified in ISO 14644-three. It requires the following 10 exams:

Division defines the probability from the dangerous product remaining present within an ignitable focus within the bordering ambiance.

OTHER ISSUES In an effort to Consider and validate cleaning procedures some suppliers have processed a placebo batch inside the equipment under in essence precisely the same running parameters useful for processing product or service.

The recovered solvents had been contaminated because of a lack of Manage around the reuse of solvent drums. Drums that were accustomed to keep recovered solvents from a pesticide output method were being later accustomed to retailer recovered solvents useful for the resin manufacturing system. The company did not have sufficient controls around these solvent drums, did not do suitable testing of drummed solvents, and did not have validated cleaning techniques to the drums.

Intrinsically Protected techniques are usually used in instrumentation and Command applications. Intrinsically Safe and sound programs don't release electrical or thermal Electrical power to bring about ignition. Intrinsically Protected techniques typically use Zenner barriers or Galvanic isolation.

The swabbing system can be employed for sampling of irregular surfaces, especially for equipment. Swabbing is utilized to dietary supplement Make contact with plates for normal surfaces. The swab is then positioned within an acceptable diluent along with the estimate of microbial count is finished by plating of the proper aliquot on or in specified nutrient agar.

Piping and valves must be tagged and simply identifiable by the operator carrying out the cleaning functionality. get more info Occasionally, inadequately recognized valves, the two on prints and physically, have triggered incorrect cleaning practices.

For Course I areas, the enclosure ought to be strong adequate to include the arc/spark or explosion within the enclosure itself and should be made these the incredibly hot fuel developed In the enclosure is adequately cooled since it escapes the enclosure.

Just one occasion which amplified FDA consciousness of the likely for cross contamination as a result of insufficient methods was the 1988 remember of the finished drug merchandise, Cholestyramine Resin USP. The majority pharmaceutical chemical utilized to make the item had come to be contaminated with minimal levels of intermediates and degradants from the manufacture of agricultural pesticides. The cross-contamination in that scenario is considered to have been a result of the reuse of recovered solvents.

Obtaining GMP get more info compliance calls for the implementation of GMP-grade supplies from well-characterised sources, underscoring the necessity of excellent in all facets of cleanroom Procedure.

Cleanroom monitoring is an essential ongoing exercise that makes certain the operational integrity and compliance on the cleanroom setting article-release.

Notify Concentrations—Microbial levels, specified in the regular working methods, which when exceeded should end in an investigation to ensure that the process is still within Manage. Alert levels are specific to get a offered facility and are founded on The premise of a baseline produced below an environmental checking method.

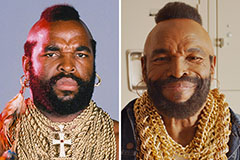

Mr. T Then & Now!

Mr. T Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Shane West Then & Now!

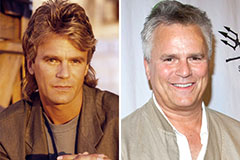

Shane West Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!